Home » New drums

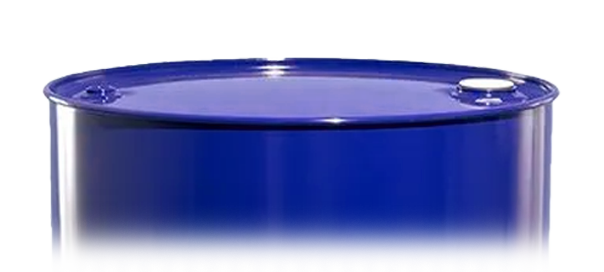

New 210L steel drums

We lead the industry in manufacturing 205-litre steel drums and provide a wide range of options for your business needs, including custom branding and colours tailored to your exact requirements.

Explore some of our most common configurations below, or contact us to discuss your specific requirements directly.

If you need reconditioned drums, visit our dedicated page to see our full range of reused drum options.

Customise your new drums

Build a drum to your exacting requirements by taking advantage of some of the available customisation that we provide for our 205 litre drums.

Tight head new drums

Tight head drums feature a welded lid that stays permanently attached to the drum body.

You fill or empty the contents through a 2" or 3/4" closure built into the top of the drum.

Open top new drums

Open top drums (also called clip top or open head drums) use a removable lid secured by a metal locking ring. You can choose a plain lid or one fitted with both a 2" and 3/4" closure, making it ideal for decanting or pumping.

UN approved

UN approved drums meet the standards and measures required for transportation throughout the UN, and are each printed with a UN identification number.

Non-UN approved

Non-UN barrels do not need to meet the same standards, and do not need to be printed with UN numbers.

Lacquer lined

Lacquer lined barrels use a premium internal lacquer to protect against corrosive contents or materials that could cause rust, or to make the barrel suitable for holding food-grade products.

Plain interior

Plain interior drums do not have a lining and the product used will be exposed to the plain steel on the inside of the drum.

One colour

We can print your barrels in a wide range of colours. Get in touch with our team to discover your options.

Dual colour

We can also dual colour your barrels, with the option of having either the top and bottom, top and middle or bottom and middle drum bands being the same colour.

New drum branding

We can print your logo or branding on either the top or center drum bands. These can be printed in a number of colours.

Clips, bungs and vents

Finally, we offer a multitude of bungs, vented caps and clips to meet your drum requirements. We stock these in a variety of colours to compliment your branding and drum design.

Now you have some understanding of what you might need,

call or email us to discuss the next steps.

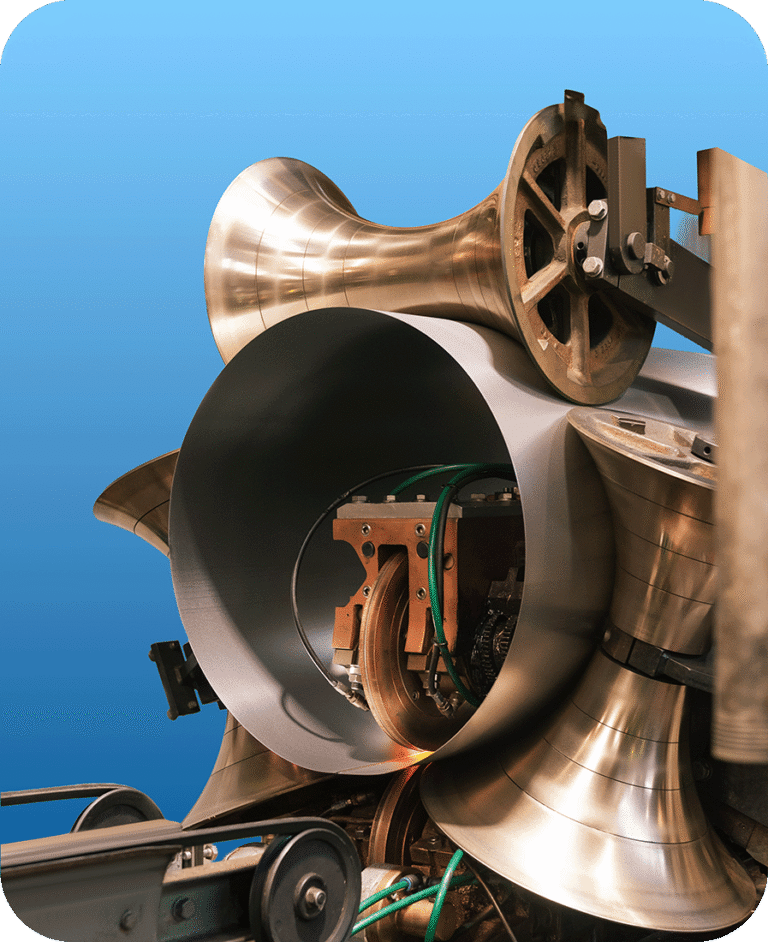

How it's made

From plain steel sheets to precision forming, welding, assembly, spraying, screen printing, packaging, and delivery – Ramsden Drums drives the entire process. We don’t just make drums; we craft them with expertise at every stage, and we’re always ready to help.

Curious to see our work in action?

Watch our latest drum-making video by watching our video.